META Project

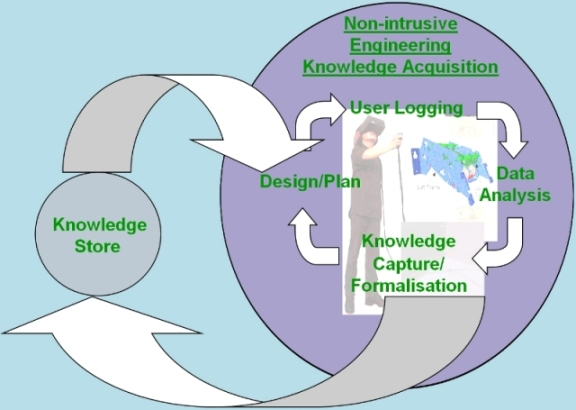

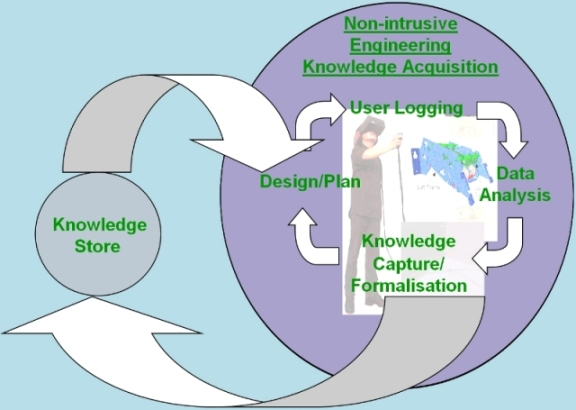

The capture and formalisation of product engineering knowledge and rationale is a fundamental problem which has affected industry for many, many years. It is only now that the integration of the tools and techniques, developed in different fields, can be brought together to examine how this can be done in a non-intrusive way. The planned research in the META project will be the first to attempt this approach by automated logging of users as they carry out a design task and then analysing the resultant log files to extract and formalise the embedded design knowledge. The captured knowledge can be archived in a product lifecycle management (PLM) system for dissemination and for training. In addition, the captured knowledge can also be used as a basis for an interactive online help system to ‘push’ information to new users who are carrying out a design task that has been completed previously by an expert user, and captured by the system.

Demonstrating the capability of capturing such knowledge and rationale at minimum cost will be central to the competitiveness of any knowledge-based economy. The concepts developed here will also be applicable to a wide range on engineering and non-engineering domains. The latter will be pursued as the results of this research become apparent. It is also hoped that this work can be exploited by a CAD/CAM vendor and incorporated into a proprietary mechanical engineering software package as well as the industrial partners.

META Project Experiments

Initial experiments to be carried out in the project will involve logging a user’s actions as they carry out a design task using a 2D CAD workstation. Types of user action that will be automatically and unobtrusively logged in the background will include the menu options selected, changes made to the design, and all keyboard and mouse input. Furthermore, using a biofeedback measurement device, the user’s bio-physiological properties can be measured and analysed to gain further insight into the user’s behavioural aspect. At a later stage, the experiments will be repeated using a stereoscopic projection system in place of the workstation.

META Project Partners

Industrial Partners: Agilent, BVT Surface Fleet, ITUNA Solutions, MBDA, Renishaw, Rolls-Royce, Selex, SGI, Virtual Interconnect

Academic Partners: COAT Laboratory (University of Basel), Italian Institute of Technology, University of Bath, University of Brasov, University of Strathclyde